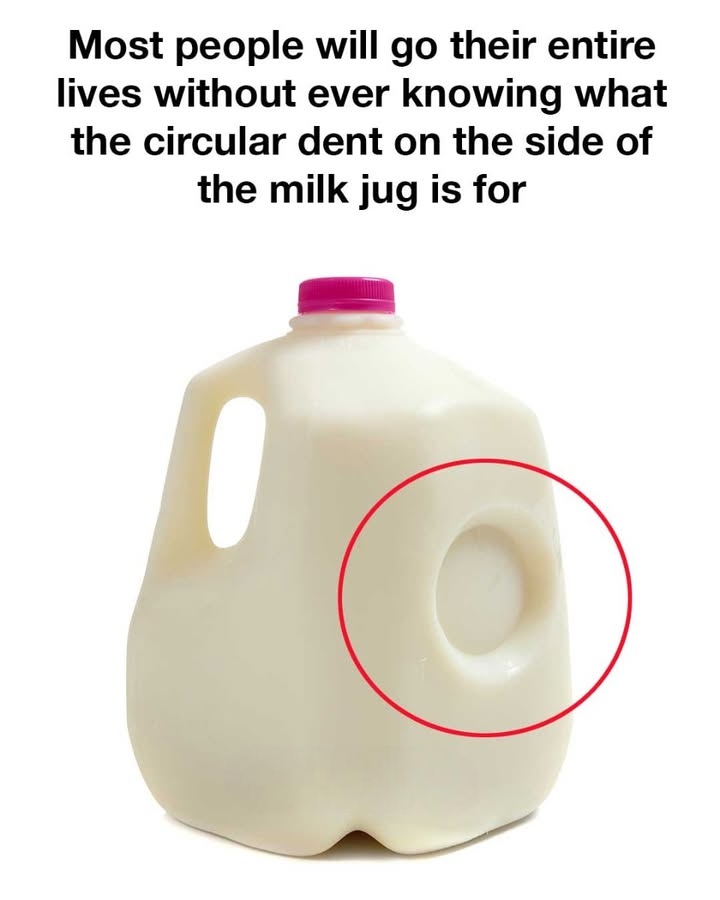

Most people see the circular dent on the side of a milk jug every day and never think twice about it, assuming it’s just a manufacturing detail or a quirky part of the jug’s appearance. But this small indentation actually plays a critical role in how the jug functions. Far from being random or decorative, the circular dent is a carefully designed feature that improves the safety, durability, and sustainability of milk containers. Its purpose is rooted in practicality and engineering, serving multiple functions that make milk jugs more reliable and efficient.

The primary reason for the dent is to manage pressure. During transport and storage, milk jugs are exposed to changes in temperature that can cause the liquid inside to expand or contract. The dent acts as a built-in pressure release zone, allowing the jug to flex slightly when pressure increases, rather than cracking or leaking. This makes the jug more resilient in unpredictable conditions, especially when it’s stacked with other containers or subjected to long-distance shipping. On top of that, the dent also reinforces the jug’s overall structural integrity. Without it, the jug might be more prone to collapsing or weakening when under stress. As plastic became the material of choice for milk containers in the mid-20th century, designers needed a lightweight, shatter-resistant solution that could withstand the demands of modern distribution systems.

The circular dent emerged as part of this evolution. Compared to the old days of heavy, breakable glass bottles, plastic jugs with built-in pressure management features represented a major leap forward in convenience and reliability. The dent doesn’t just help the jug hold up under pressure—it also makes the production process more efficient. Because the dent adds strength to the jug without requiring more material, manufacturers can use less plastic in each container, which cuts down on costs and reduces environmental impact. This clever approach allows for mass production that’s both cost-effective and better for the planet. By using less plastic overall, companies not only save money but also contribute to a reduction in plastic waste. That small indentation is a smart example of how good design can support both business goals and environmental responsibility.

Consumer safety is another benefit that often goes unnoticed. If a milk jug is dropped, the dent helps absorb some of the impact, making it less likely to burst or spill. This can be especially helpful in homes with young children, where spills are more common. By reducing the chances of a messy accident, the dent adds an extra layer of protection that helps preserve the contents and prevent waste. From a recycling standpoint, the dent plays a surprisingly useful role as well. The design makes the jug easier to compress and crush, which simplifies the recycling process and reduces the amount of space needed to store and transport empty containers. This supports the broader effort to create a circular economy, where materials are reused and kept out of landfills. Every bit of plastic that can be efficiently recycled helps reduce pollution and conserve resources.

While the dent’s main role is functional, it can also be used as a branding opportunity. Some companies have chosen to incorporate their logos or other visual elements into the dent, turning it into a subtle design feature that catches the consumer’s eye and reinforces brand recognition. In this way, the dent becomes more than just a structural feature—it also contributes to a product’s shelf appeal and marketability. Despite all these practical advantages, the circular dent is still misunderstood by many. Some people assume it’s a defect or an accidental flaw, unaware of its purpose and significance. Others believe it serves no purpose at all. These common misconceptions show just how often consumers overlook the thought and engineering that go into even the simplest products. Educating people about the function of the dent not only clears up confusion but also increases appreciation for the everyday innovations that make our lives easier. In conclusion, the circular dent on a milk jug is a small detail with a big impact. It supports pressure control, improves structural strength, reduces material use, enhances safety, and promotes recyclability—all while remaining almost invisible to the average person. Once you understand its purpose, you’ll never look at a milk jug the same way again.